Compound Spotlight : Acetaldehyde

Category: Usually undesirable

Aroma: Green apple, Pumpkin rind

Threshold (in beer): 5-10ppm depending on the style

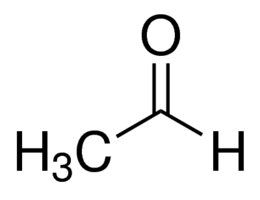

Fig. 1 Chemical structure of Acetaldehyde

Introduction to Acetaldehyde

What is Acetaldehyde and How is it Formed?

Acetaldehyde is formed by all yeast. As yeast undergoes fermentation, glucose is turned into pyruvate then acetaldehyde, and finally ethanol. Yeast utilizes this metabolic pathway of glycolysis to maintain levels of ATP, adenine triphosphate, aka the energy currency of the cell. As figure 2 shows below, acetaldehyde changes to ethanol with NAD+ regeneration.

Fig 2. Metabolism Pathway

Controlling Acetaldehyde

If acetaldehyde is always present in all yeast metabolisms, how do we control it? High levels of acetaldehyde are usually associated with green or young beer. As you let the beer mature and condition on the yeast, yeast cells will reabsorb the acetaldehyde and convert it to ethanol. Higher fermentation temperatures can speed fermentation timelines but it will also cause more compounds to be produced such as acetaldehyde. Proper pitch rates and yeast health is important for reabsorbing acetaldehyde.

To ensure healthy yeast, wort oxygen before pitching is recommended. Optimal aeration is around 8-10ppm depending on the style. Oxygen is needed for building sterols and fatty acids which helps the transport of compounds in the yeast cell membrane.

Oxidation may also cause the reappearance of acetaldehyde.

Another aid to controlling acetaldehyde is adequate zinc levels. Zinc is a cofactor in the enzyme alcohol dehydrogenase as it helps facilitate and speed up the reaction from acetaldehyde to ethanol.

Target zinc levels range from 0.15 to 0.5ppm for healthy fermentations.

Servomyces, is an organic yeast nutrient that contains naturally zinc enriched yeast hulls which can help reach target zinc levels when added to the hot side.

Testing

Through White Labs Analytical Laboratory, we can provide quantitative results to help track acetaldehyde and zinc levels.

Here are two laboratory analysis tests White Labs offers:

Comprehensive Flavor Profile - SIT0031 - Panel for monitoring and analyzing common esters and fusel alcohols. Contains acetaldehyde in the panel.

Zinc - SIT9001 - Great for determining zinc levels of wort before fermentation.

- TECHNICAL

- June 28, 2024

- TECHNICAL

- June 17, 2024

- GENERAL

- June 11, 2024

Yeast & Bacteria Bank

Yeast & Bacteria Bank

Enzymes & Nutrients

Enzymes & Nutrients

Lab Services

Lab Services

Education

Education

Merchandise

Merchandise